|

Designing a Project Designing a Project

Translating the Design into Cutting Instructions Translating the Design into Cutting Instructions

Cutting Segments Cutting Segments

Gluing and Clamping Rings Gluing and Clamping Rings

Flattening Rings Flattening Rings

Gluing up the Project Gluing up the Project

|

|

When cutting segments to make a ring, accuracy in both

its length and cutting angle is important both for the cost of what you

make and the result you obtain. If the angle is not precise, you will

get gaps; they will be on the inside of the rings if the angle is too

large and on the outside if the angle is too small. If the length is

irregular, you will also get gaps. Finally the ring will be too large

or small depending on if the length is long or short.

Just what is the best way to cut your segments? I think I've tried

them all. And, recently, I found a new way that I think beats all

others for accuracy and ease of setup, and time spent. It's the MiterSet tool.

It makes only 2 assumptions about your table saw.

1) The saw blade is parallel to the miter slots.

2) Your miter guage fits sugly in the tool and the slots in your saw's table top.

You have full control over

the former and you ought to be able to address the latter as well.

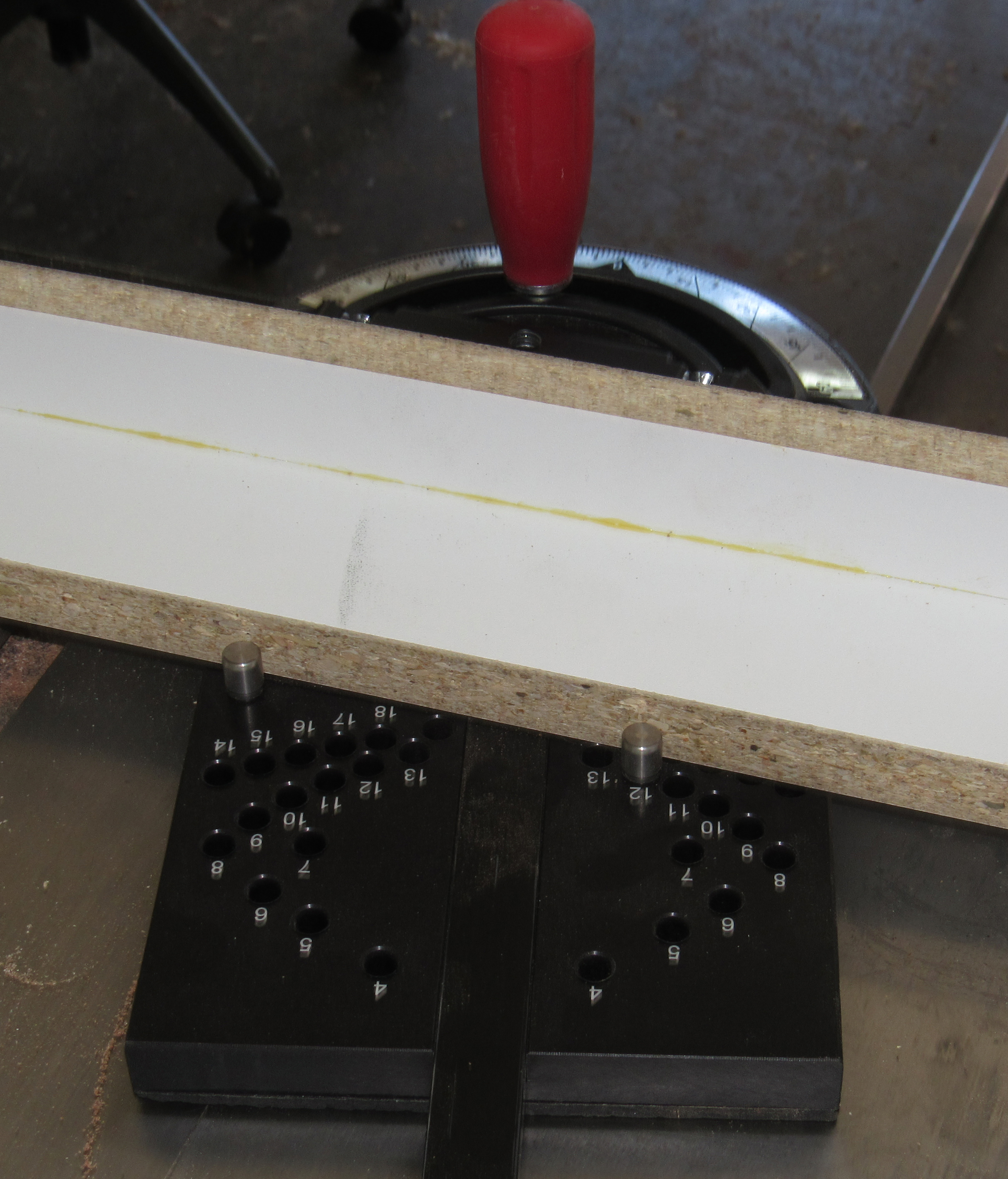

Setup is really simple as shown in this first picture. Place your miter

guage in the tool's slot, set the 2 pins for the number of sides

needed, loosen the lock, and set the face of the miter guage

firmly against the pins. One pin sets the zero point while the other selects

the number of sides. Using the one tool, you can set for any number

of sides from 4 to 20, except 19. The tool is set up symmetrically, so

you can set up for either leading or trailing cuts.

|

|

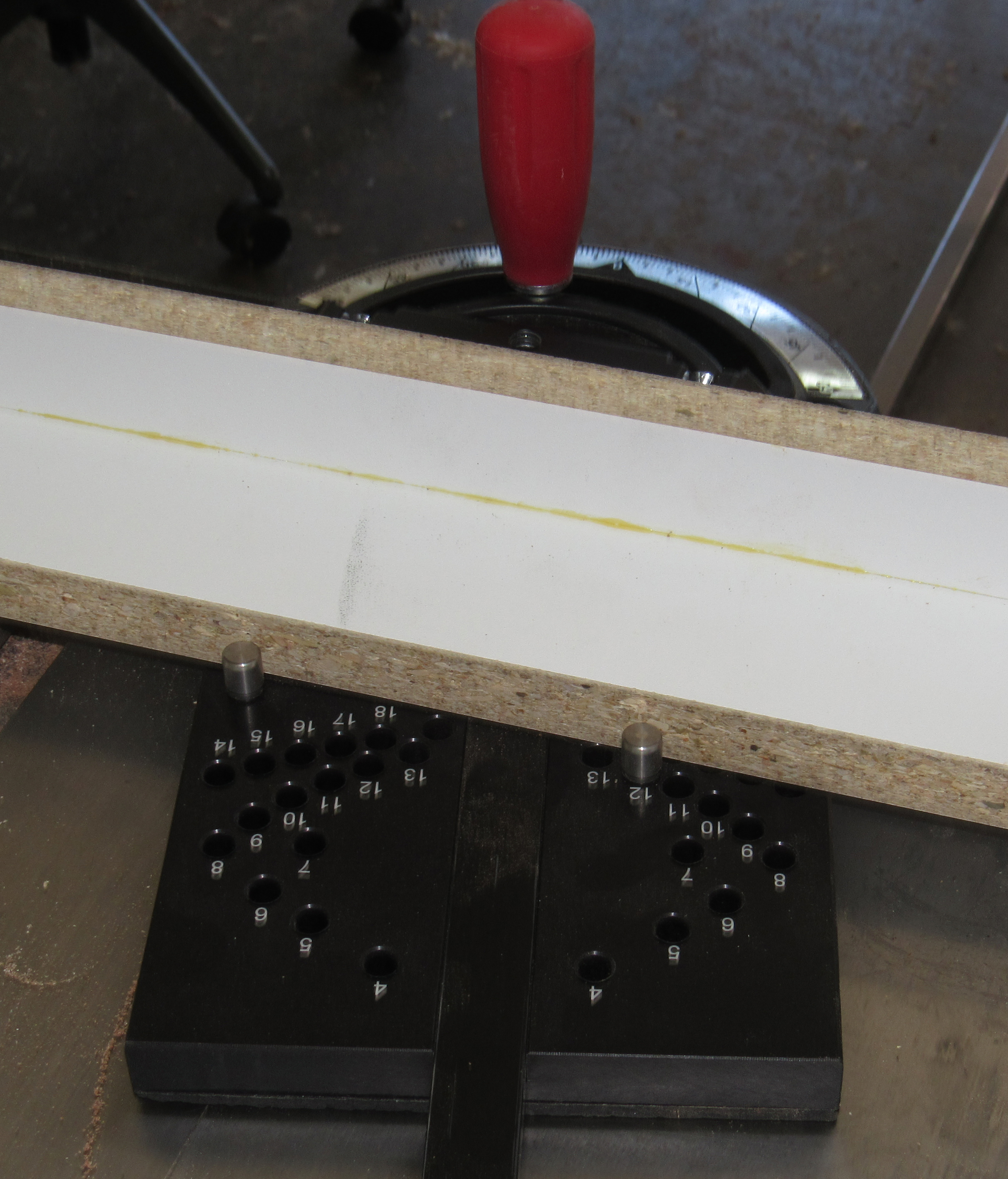

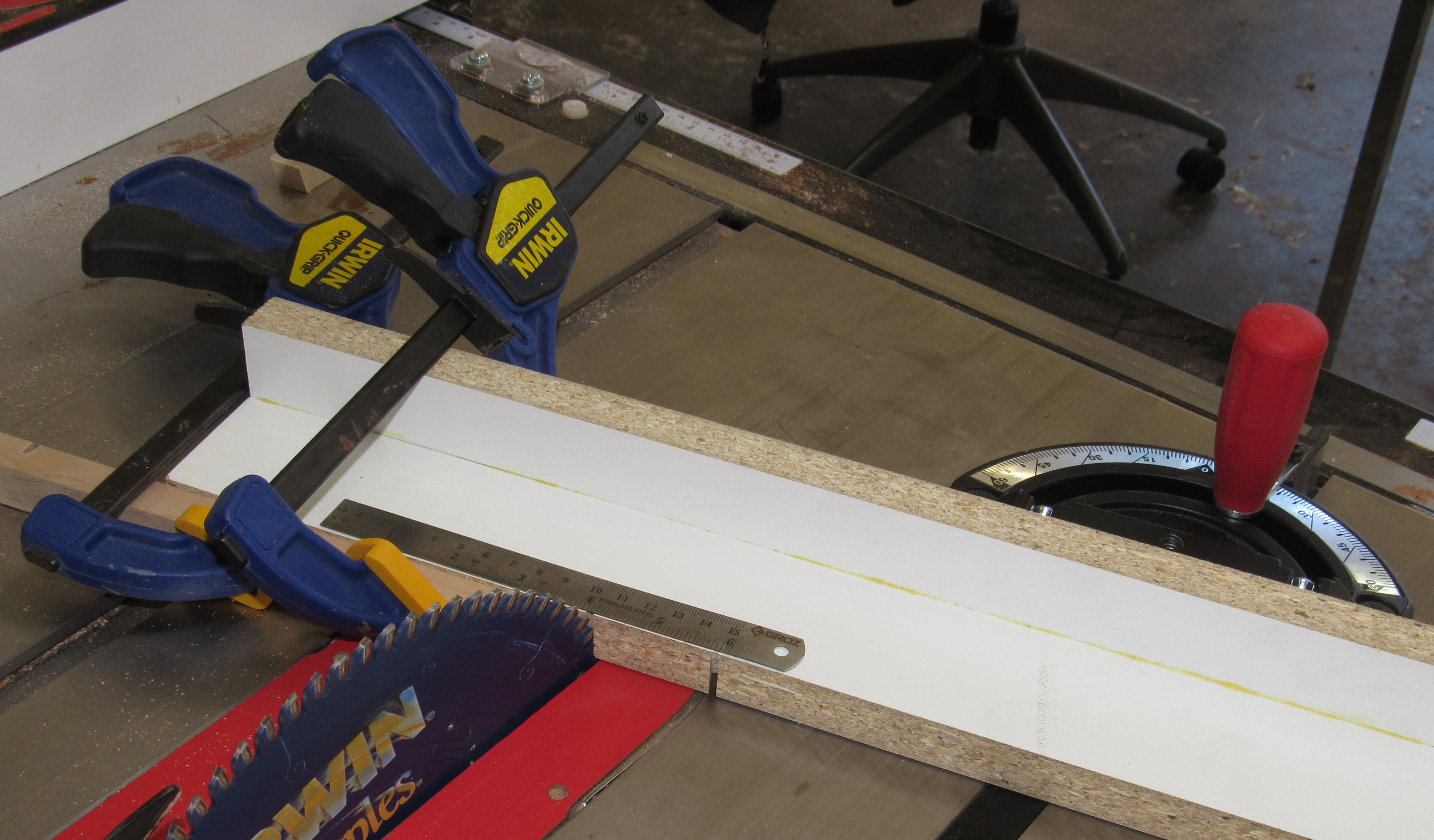

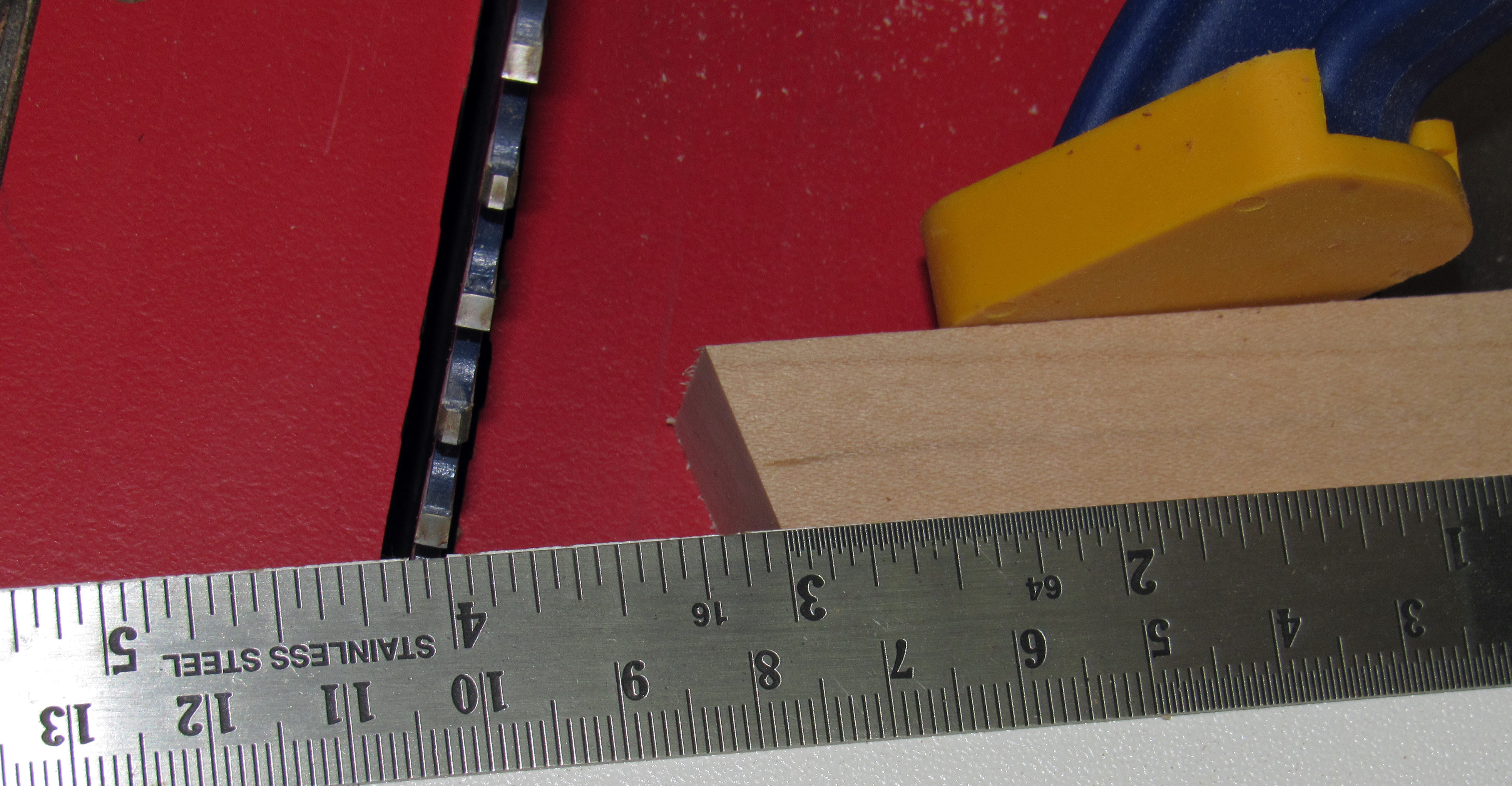

The setup for cuttting is simple as well. The first picture shows it as

being a simple glue-up of two boards attached to the miter guage so that the board extends

well across the saw blade. The horizontal member is 3 inches wide and

the vertical member is just tall enough to match the height of my miter

guage. That's 1 1/4 inch for me.

The placement of this assembly extends well across the saw blade, providing

ample room for clamping my stop block as well as the longest segment to

be cut.

Choosing 3" for the horizontal member of the

assembly was so its extension across the saw blade would never be cut

off. Existance of the extension supports the segment being cut so the

cut face of the segment is clean and free of tits. Its existance with a

thickness of 3/4" also enables easy measuring/positioning for the stop block as

seen in the second picture. |

|

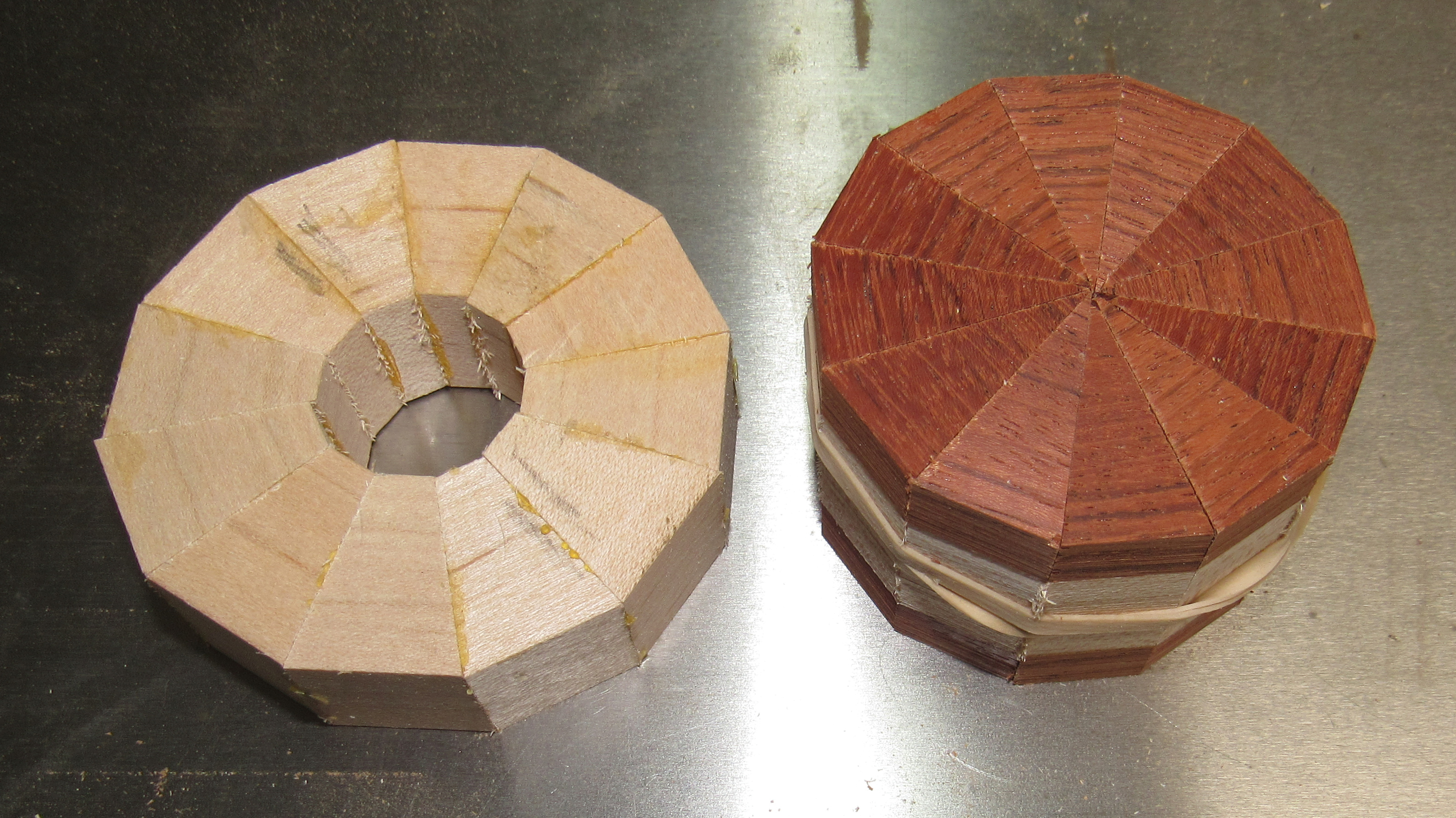

And the last question. What about the accuracy?

MiterSet claims accuracy to within .001 degrees. I've only made 19

rings with it so far, for 12 and 18 sided objects, but the results

are impressive. I've been able to go from cutting to gluing without

adustment. The Maple ring below shows no gaps. The Jatoba ring has just been cut and is

bound in a rubber band to check the fit. To the right is that same set

of Jatoba segments glued up with 7/8" vertical spacers. No adjustment

was required.

Can you expect to get zero adjustent every time? That's probably impossible! But

most of your attempts ought to come out that way. That means less time spent making rings and calibrating miter sleds..

The Miterset tool works with most U.S. made table saws and will cost you $99.99. It's a lot cheaper than an Incra tool and more than the cost of making your own miter sled.

Click here to visit miterset.com

and learn all about it. |

|

When you set up for cutting segments using a chop saw, miter sled, or band saw, the blade needs to be as close as

possible to vertical. The closer you can get it, the flatter will be the rings you glue up from the segments.

When you cut segments to make a simple ring, you have two basic methods. For what I call the "Economy" method, you

flip the stock you are cutting from over for each cut to take advantage of the edge you just cut. This method gives you

the maximum number of segments for a given length of material. But, since the grain can vary somewhat from one side of the

stock to the other, each segment will be basically unrelated to its neighbor.

For what I call the "Grain Matching" method, you keep the same side of the stock up throughout the entire set of

segments for the ring. To do this you have to turn the stock over and cut a new face. Then turn it back over, to the

original side up, and cut the next segment. The "Grain Matching" method will use 10% to 54% or more material than the

"Economy" method depending on the ring size and the thickness of the wall. This is the price to be paid for having

segments where the grain walks from piece to piece. Sometimes it's worth it!

|